Topical

Valves

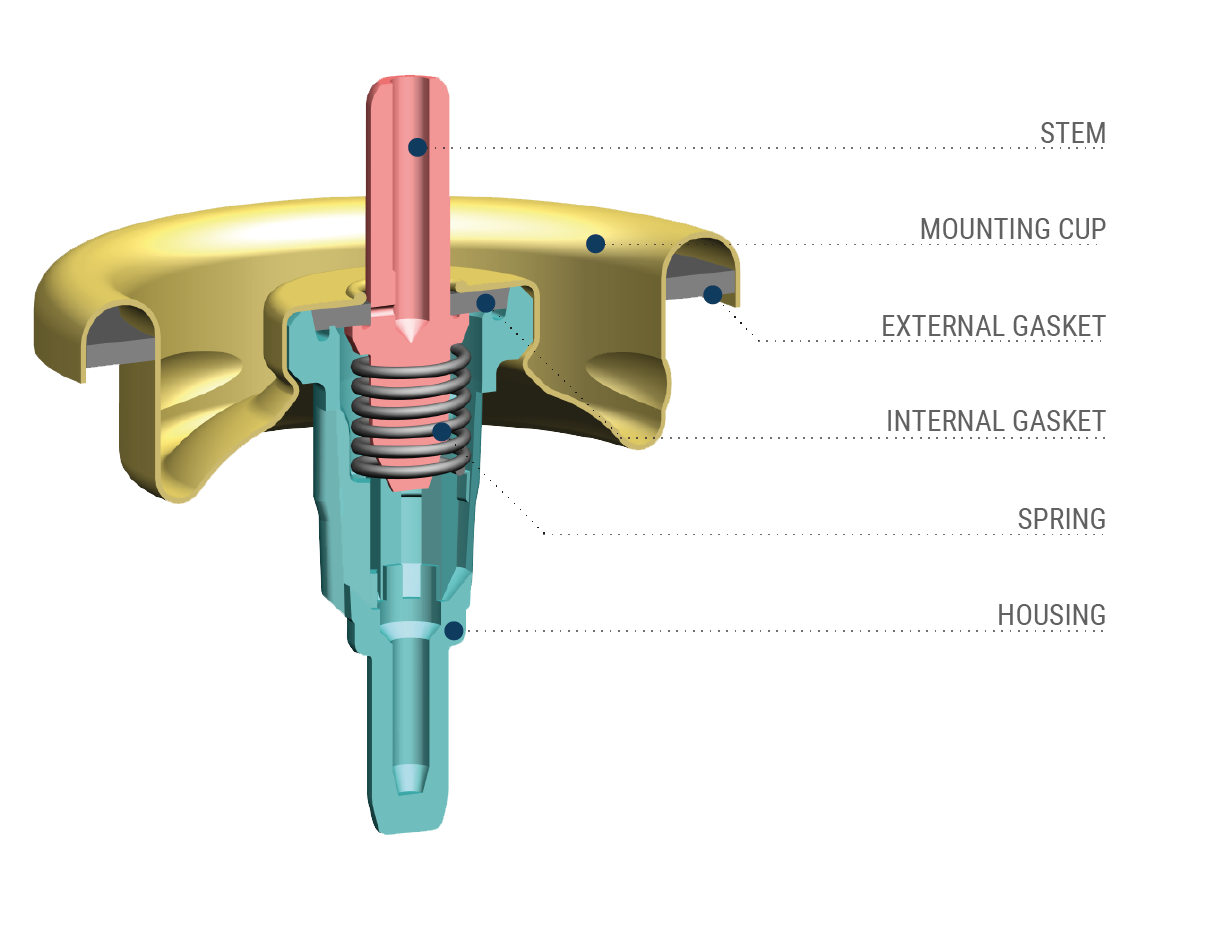

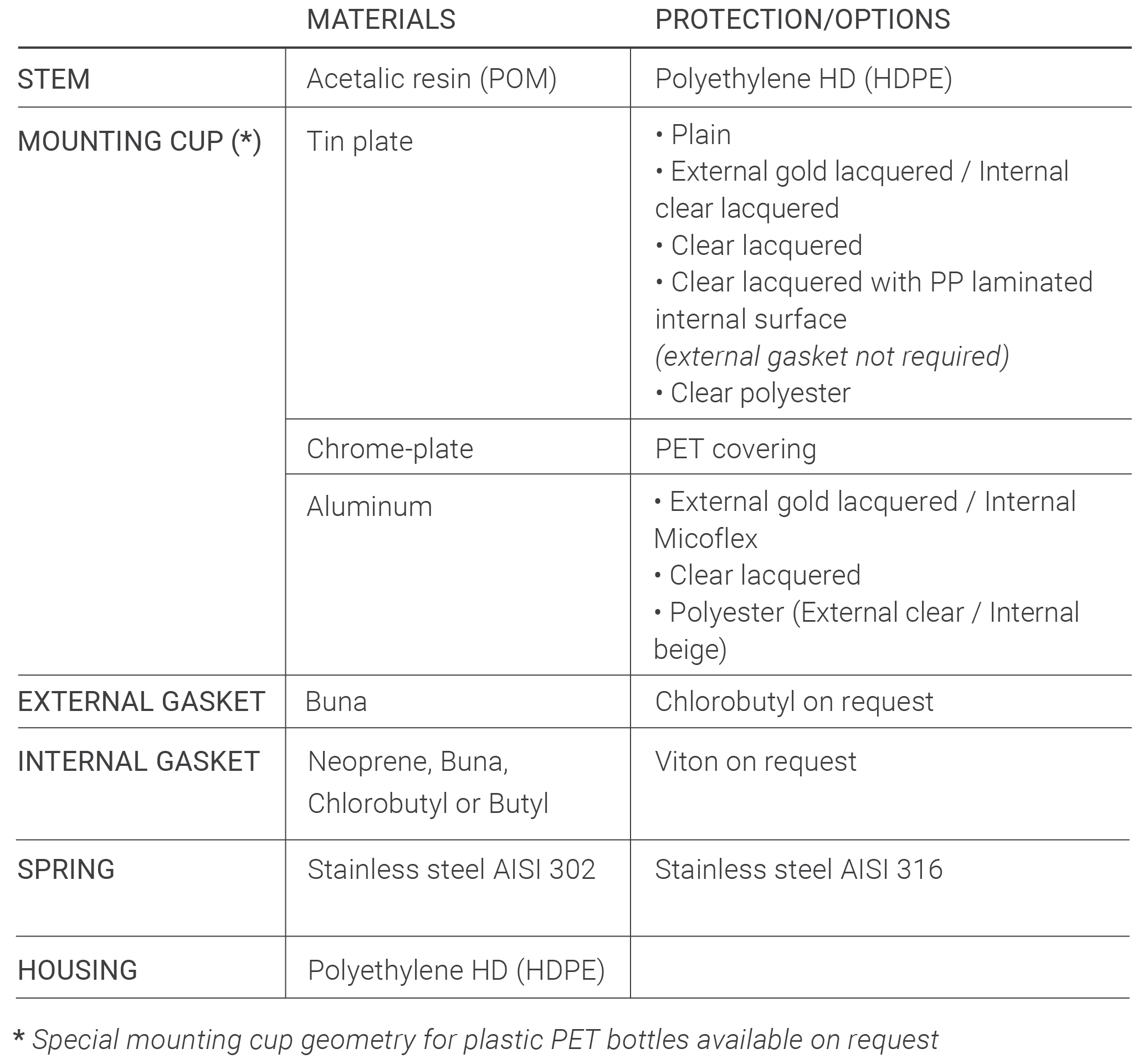

Continuous valve for upside down use

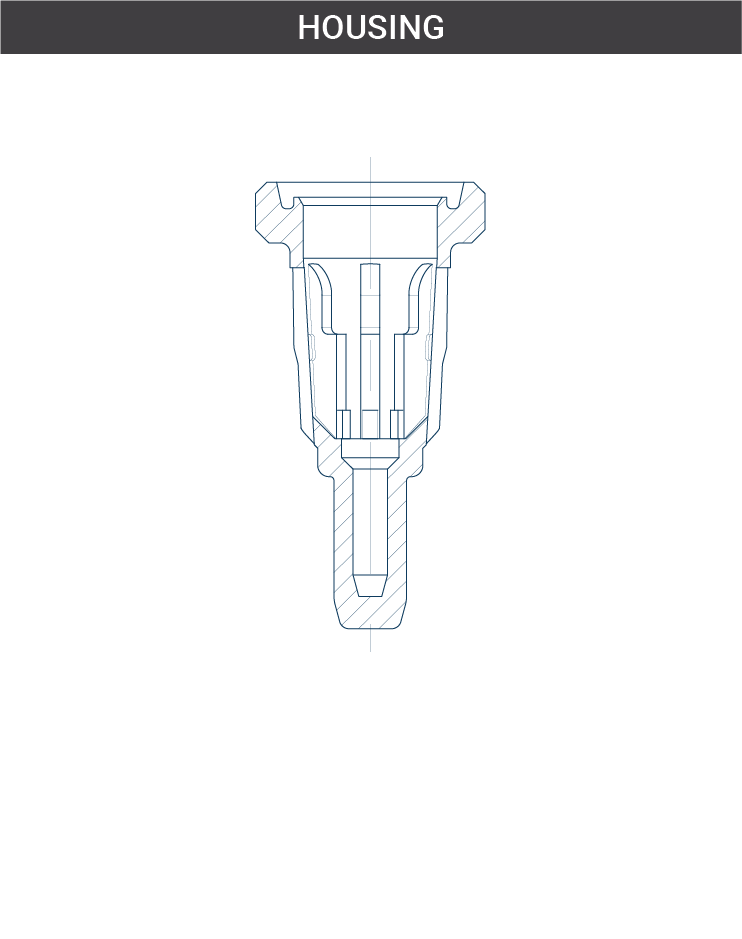

The NKR valve is equipped with a housing with two side slots, that permits the complete emptying of the can in the upside-down position.

The valve does not need a dip tube. Nevertheless, the housing is supplied with a tang where a dip tube can be inserted in order to facilitate the selection of the valves in the automatic feeding machine.

NKR valves are generally employed for products that must be actuated in inverted position, such as hair mousse, cosmetic creams, food products, road markings paints, etc.

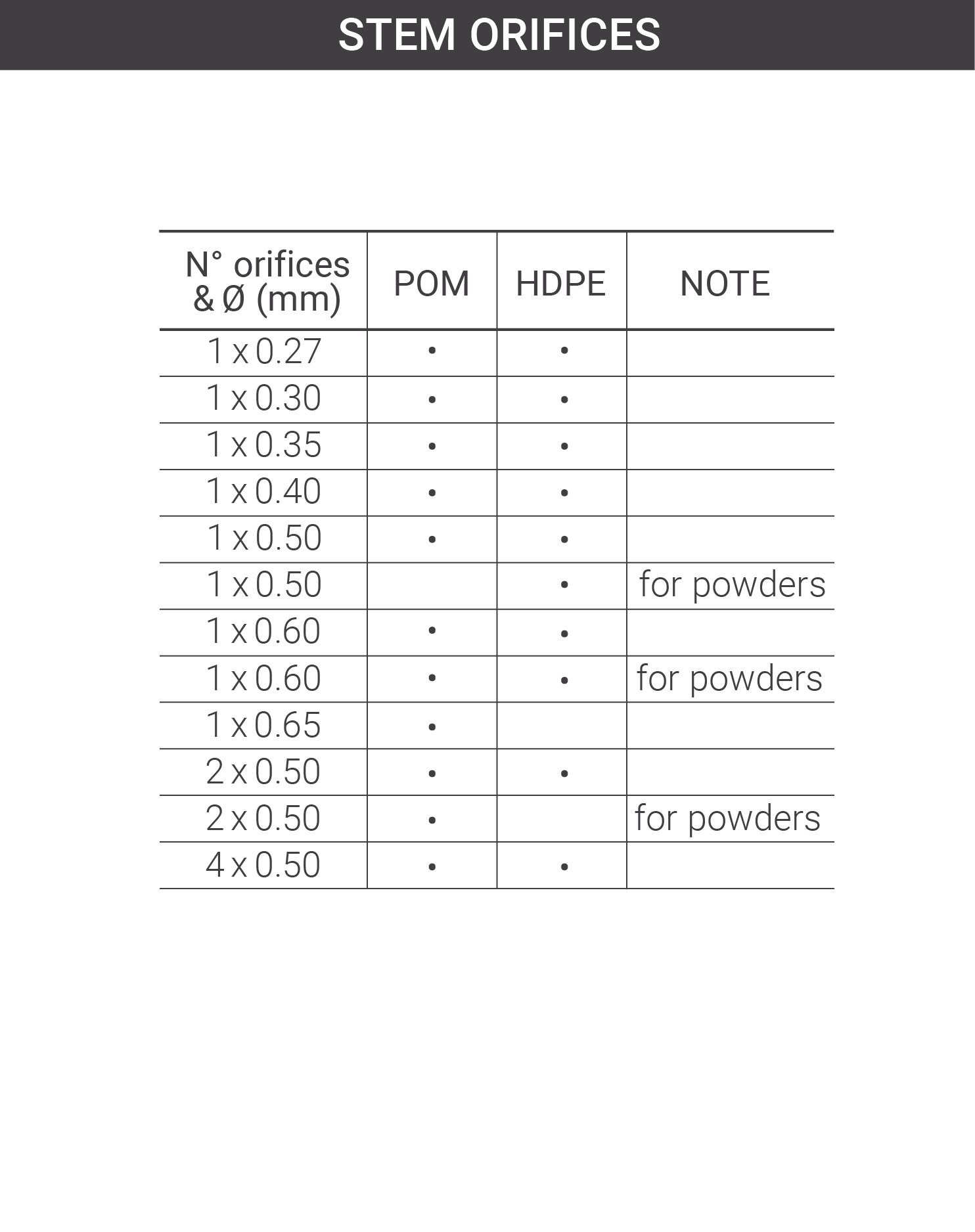

TECHNICAL SPECS

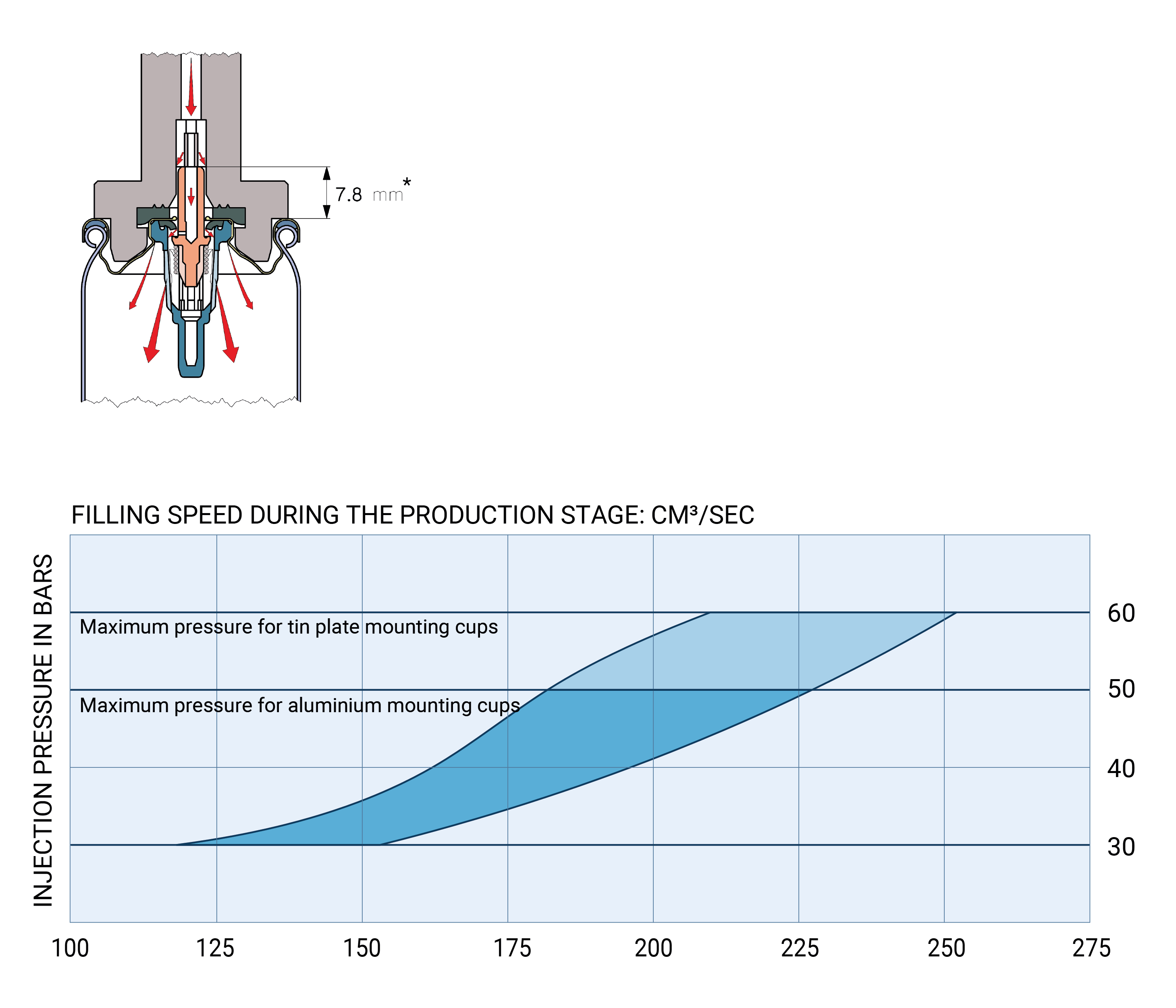

FILLING METHODS AND FILLING SPEED GRAPH

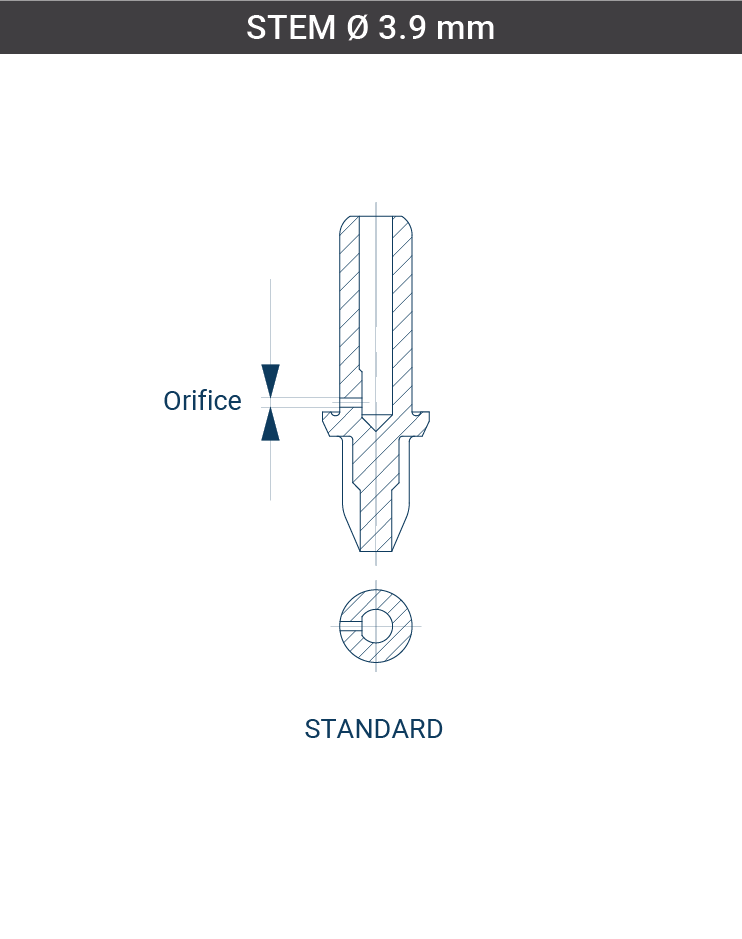

For these valves the mechanical opening of the stem is necessary.

(*): Suggested dimension that must assure mechanical opening 1.5 ± 0.3.

The filling speed graph refers to butane-propane propellant.

It is purely indicative, as it is based on historical data.

The filling speed depends on the injection pressure, on the characteristics of the filling

machine and on the dimensions of the valve’s components (shape of the stem, number

and diameter of the orifices).

Given the high number of parameters that can cause significant variations in the quoted values, if specific information is required please ask Coster commercial offices to obtain precise data on a specific model.

Topical

RxPack's product offering includes multiple valves for topical applications, from continuous to metering, upright or inverted positions, and 360° use. The range is completed by a comprehensive actuator portfolio enabling to dispense of liquids, powder-based formulations, foams, and highly viscous products. Specific features apply when used in combination with compressed gasses, HFA, or butane-propane blends.